A University of Houston engineer has developed a powerful biodegradable alternative to plastic using bacterial cellulose. This scalable innovation could revolutionize packaging, textiles, electronics, and more while helping to reduce global plastic pollution.

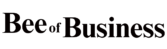

Dr. Maksud Rahman, an assistant professor of mechanical and aerospace engineering, has developed a new biodegradable material made from bacterial cellulose — a natural, earth-friendly substance that could become the next big alternative to plastic. From disposable water bottles and packaging to medical wound dressings, Rahman’s innovation opens the door to sustainable, multi-use materials grown with the help of nature itself.

“We envision these strong, multifunctional and eco-friendly bacterial cellulose sheets becoming ubiquitous, replacing plastics in various industries and helping mitigate environmental damage,” said Rahman.

The work, recently published in Nature Communications, showcases how Rahman and his team turned a naturally occurring biopolymer into a versatile material that’s strong, flexible, transparent, and stable — qualities that are essential for everyday items currently made from plastic.

A Simple Yet Powerful Breakthrough

So how does it work? Rahman and his team including M.A.S.R. Saadi, a doctoral student at Rice University and the study’s first author discovered a way to guide bacteria to produce cellulose more efficiently and with greater structural integrity. Instead of allowing the bacteria to move freely, they introduced a spinning cylindrical incubator that creates directional fluid flow. This encourages the bacteria to travel in a single direction, which, in turn, helps them build highly aligned, stronger nanofibrils.

“We’re essentially guiding the bacteria to behave with purpose,” explained Rahman. “Rather than moving randomly, we direct their motion so they produce cellulose in an organized way.”

This technique leads to bacterial cellulose sheets with remarkable strength — all without harmful chemicals or complicated steps. And because the process is simple and scalable, it could be adapted for large-scale production in various industries.

Strength in Nature: Boosting Cellulose with Nanotechnology

To make the material even stronger and more functional, the team mixed boron nitride nanosheets a nanomaterial known for its excellent thermal properties into the bacteria’s feeding solution. The result? Hybrid nanosheets with significantly improved mechanical strength (up to 553 MPa) and three times faster heat dissipation than conventional samples.

That means these sheets aren’t just sustainable — they’re high-performance.

“This scalable, single-step bio-fabrication approach yielding aligned, strong and multifunctional bacterial cellulose sheets would pave the way towards applications in structural materials, thermal management, packaging, textiles, green electronics and energy storage,” Rahman noted.

Read More: Auto-rickshaw driver Anik Mia returns 1.5 million taka left behind by a passenger

For decades, the world has relied on petroleum-based plastics cheap, versatile, but environmentally disastrous. As plastic waste continues to accumulate, there’s growing urgency to find alternatives that don’t just work, but work better for the planet.

Bacterial cellulose fits that need. It’s naturally biodegradable, biocompatible (meaning safe for medical uses), and now, thanks to Rahman’s work, scalable and multifunctional.

Shyam Bhakta, a postdoctoral fellow in Biosciences at Rice University, also played a key role in the biological implementation of the research.

The team’s breakthrough shows what can happen when engineering, biology, and nanotechnology come together to solve real-world problems — starting with the plastic crisis.

“This work is an epitome of interdisciplinary science at the intersection of materials science, biology and nanoengineering,” Rahman said with pride.

In one hand, Dr. Maksud Rahman holds a sheet of bacterial cellulose — thin, strong, almost glass-like. In it, he sees something bigger: a cleaner world, where innovation and sustainability work hand in hand. It’s a small sheet, perhaps, but with massive potential.

And as global conversations shift more urgently toward climate action and reducing waste, Rahman’s work offers hope — not just for science, but for the planet.